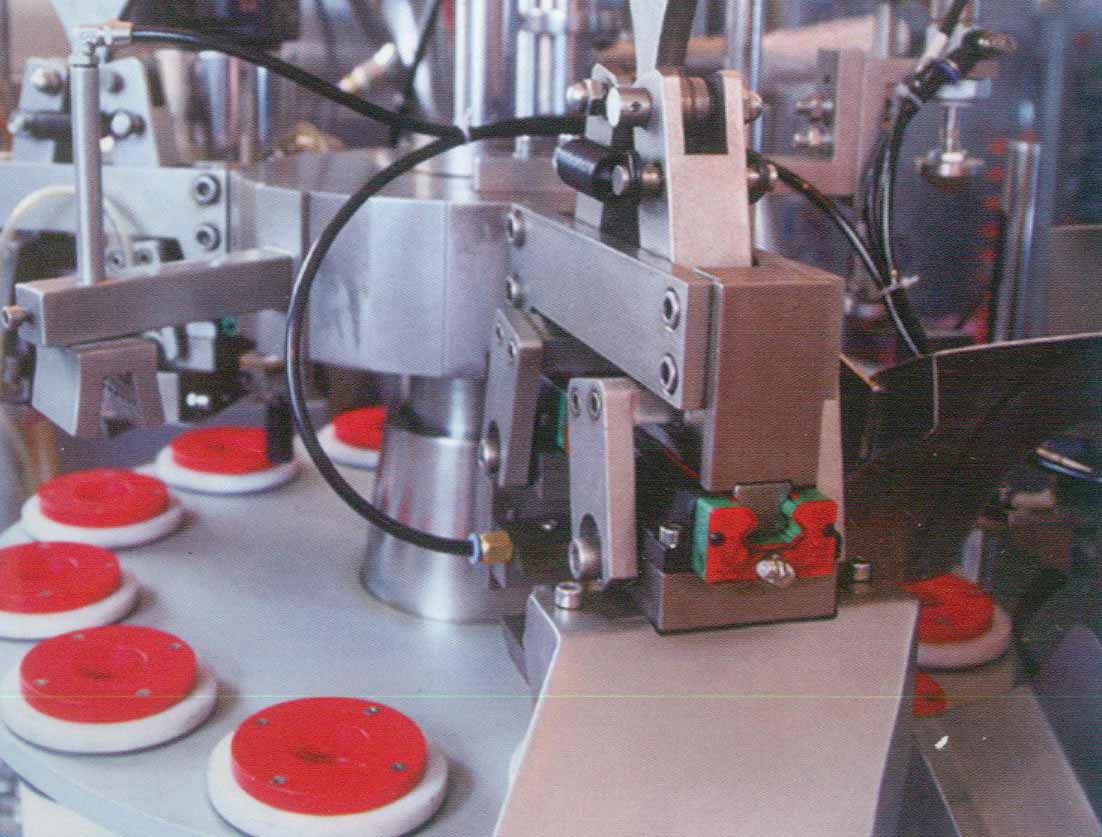

NF-60Z/60A/80A Automatic Filling and Sealing Machine

U7彩票

Feature

u With 12 working stations and matching with manipulator, the machine is able to meet different type of tail folding, sealing requirements of plumbum tube, ALU tube, plastic tube and laminated tubes. It is a multi-purpose machine.

|

Model |

NF-60Z |

NF-60A |

NF-80A |

|

Filling Speed |

60 pcs/m |

60pcs/m |

80pcs/m |

|

Filling Range |

5-180ml/pcs |

5-240ml/pcs |

5-300ml/pcs |

|

Filling Accuracy |

≤±1% |

≤±1% |

≤±1% |

|

Diameter of Soft Tube |

Φ10-φ35mm |

Φ10-φ50mm |

Φ10-φ50mm |

|

Length of Soft Tube |

50-180mm |

50-210mm |

50-210mm |

|

Tube Material |

Plastic tube, laminated tube, ALU tube and plumbum tube |

||

|

Power Supply |

380V/220V |

||

|

Working Pressure |

0.55-0.65Mpa |

||

|

Suited Motor |

1.1Kw |

1.5Kw |

|

|

Heat Seal Power |

3.0Kw |

||

|

Overall Dimension |

2000*950*1900 |

2200*1220*2400 |

|

|

Machine Weight |

850Kg |

1300Kg |

|

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

YG200 High-Speed Eysdrop Aseptic Filling Production Line

The eysdrop aseptic filling line consist of four main units including unscrambler, conveyor, pure air washer, monobloc of filling plugging and capping unit. Themachine is mainly used to accomplish bottle unscrambling, conveying, air washing, dosage discharging, plug & capplacing, The entire production process is protected under laminar flow H14 and aseptic isolation cover, which isolated all working area and keep eyedrops product be filled under aseptic environment. The regional isolation protection to ensure that the eye drops sterile production. The whole machine meet the requirements of new GMP. The production line is also suitable for the production of other similar plastic bottle.

Learn More20-500ml Plastic Bottle Syrup, Oral Liquid , Tincture Filling Line

This production line is mainly used in pharmaceutical, healthcare products such as oral liquid, syrup, liquor,healthcare product, tincture in different viscosity packing. Auto accomplish bottle unscrambling, washing, volumetric Filling, cap screwing (sealing), lnduction Sealer, labeling process. The whole machine meets the requirements of GMP.

Learn More20-500ml Glass bottles of Oral liquid, Syrup, Liquor, Healthcare products etc. Washing, Drying and Sterilizing, Filling, Capping Line

This production line is mainly used in pharmaceutical, healthcare products such as oral liquid, syrup, liquor, healthcare product, tincture in different viscosity packing. Auto accomplish bottle unscrambling, washing, drying and sterilizing, volumetric filling, cap screwing (sealing), light inspecting, labeling process. Thewhole machine meets the requirements of GMP.

Learn More