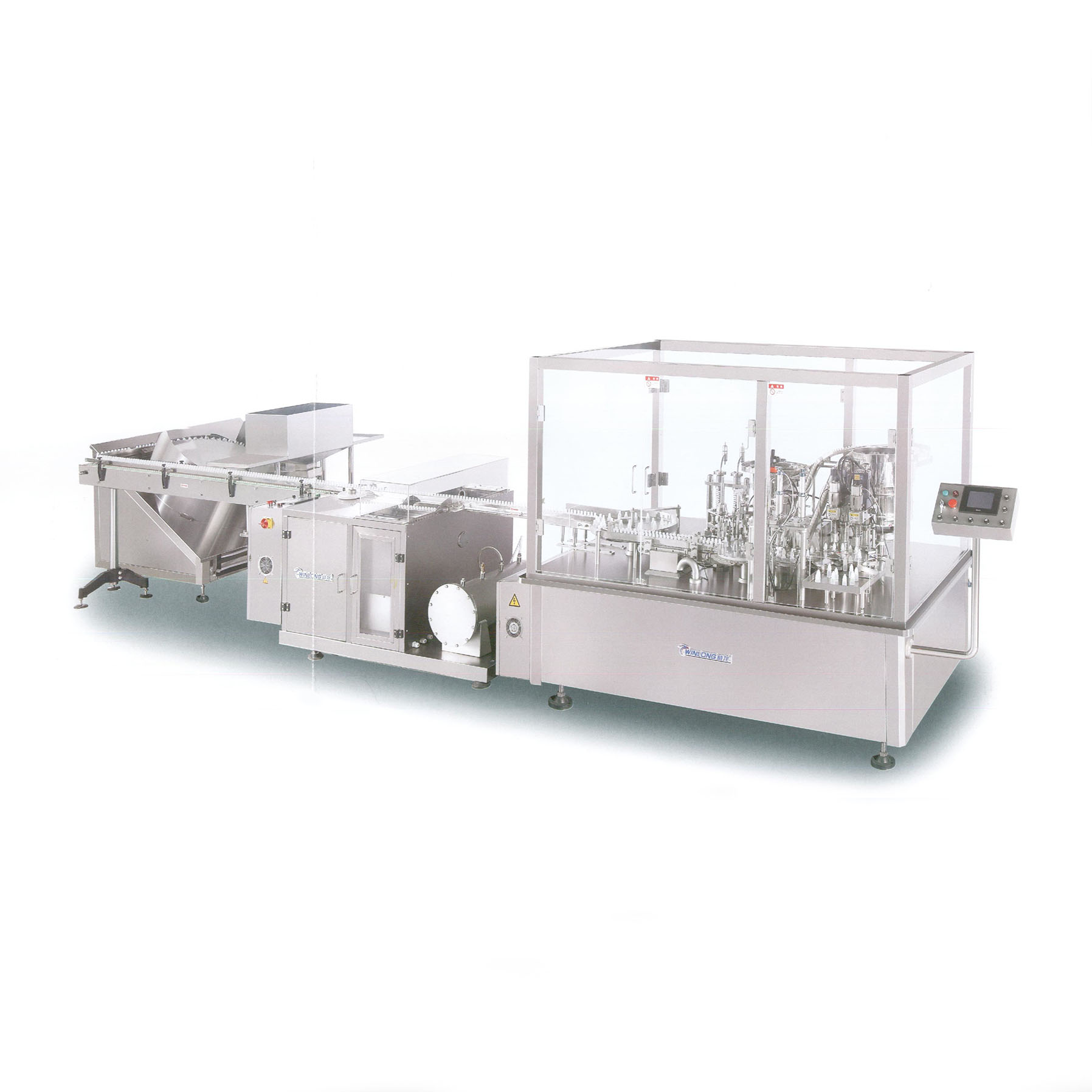

YG4/2/2-100 Eyedrop Aseptic Filling Production Line

U7彩票 The prooduction line of the eye drops is mainly to the completion of the eye drops bottle Unscrambler,bottle conveying, air wash, metering packaging, plus stuffed inside and outside screw etc processed.

- Store quantities of bottles, automatic unscrambling system

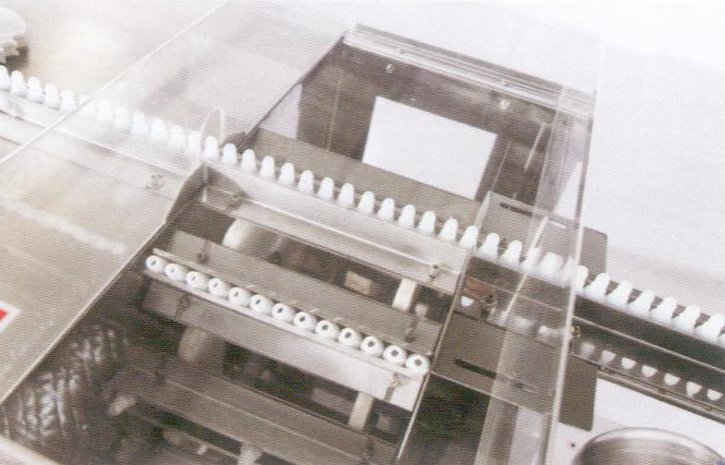

- Convoy bottle, reject inverted bottle system

- Static elimination, air washing

- Precision Ceramics, bottle indexing system

- Vacuum pick and auto place system

- Constant magnetic torque, positioning capping system

- Aseptic laminar flow protection system

- Altemative peristaltic pump system instead of ceramic pump

Main technical parameter

|

Bottle used |

5-30ml plastic bottle |

|

Production capacity |

90-120bpm |

|

Filling nozzles |

4 |

|

Bottle air washing heads |

12 |

|

Plug placing heads |

2 |

|

Capping heads |

2 |

|

Filling precision |

≤±1% |

|

Qualified bottle air washing |

100% |

|

Qualified plug placing |

≥99.8% |

|

Qualified cap screwing |

≥99.8% |

|

Compressed air required |

10m³/h 0.6-0.8MPa |

|

Total power |

≤5KW 380V(220V) 50HZ |

|

Net weight |

3000KG |

|

Overall dimension |

6780*2380*2000(Exclude LAF) |

U7彩票 Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

PXG/8 Spray Bottle Capping Machine

U7彩票This series of machines is applied for screwing spray pump onto bottle mouth in industry of pharmaceutical and cosmetic field. As for the slim and long tube of the spray pump, this machine equip manipulate guider which can lead the long tube right into bottle mouth.

Learn MoreAGF Automatic gravity filling machine

AGF automatic gravity liquid filling machine adopt logic controller PLC, 6" LCD touch screen system, ordinary pressure flow passage parameters, set the flowing time to control different quantify. It applys to pharmaceutical, foodstuff, pesticide, chemical, etc.

Learn More