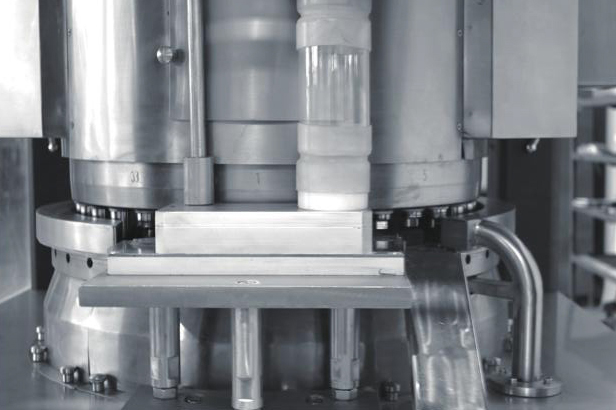

GZP-520i Double Discharging Rotary Table Press

Equipment performance

Contro lled by PLC Programme

Equip with self-lubrication system

Tablets formed from powder by prepressing and main-pressing procedure

Double-forced feeding system

Tableting room is compliant with GMP standard

Technical parameters

|

参数 |

Data |

ZP55 |

ZP49 |

ZP41 |

ZP35 |

ZP47 |

ZP39 |

|

冲模数 |

Die number |

55 |

49 |

41 |

35 |

47 |

39 |

|

最大主压片力 |

Maximum main tablet force(kn) |

100 |

|||||

|

最大预压片力 |

Main pressure(kn) |

20 |

|||||

|

最大压片直径 |

Max tablet diameter(mm) |

13 |

18 |

||||

|

最大压片厚度 |

Max Thickness of tablet(mm) |

8 |

6 |

||||

|

最大填充深度 |

Max Depth of filling (mm) |

18 |

15 |

||||

|

转台转速 |

Rotate speed(r/m) |

5-40 |

|||||

|

生产能力 |

Out-put (p/h) |

264000 |

235000 |

196000 |

168000 |

225000 |

187200 |

|

冲模直径 |

Tooling type |

BBS |

BB |

B |

D |

ZP22 |

ZP26 |

|

主电机功率 |

Main motor power |

7.5Kw |

|||||

|

外形尺寸 |

size |

1350 x 1040 x 2200 |

|||||

|

机器重量 |

Weight |

3900 |

|||||

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

GZP-540 Double Discharge Tablet Press

GZPK540 series rotary tablet press is a series of products. Mainly used in the pharmaceutical industry, but also in the chemical, food, electronics and other industries. It can produce round pieces of various specifications, special shaped shaped pieces and double-sided lettering pieces.

Learn MoreWear - Resistant Rotary Tablet Compression Machine Min 1000 Pcs Per Minute

U7彩票The machine is a single press type,continuous automatic tablet press machine for pressing granular raw materials into tablets.Rotary tablet press is mainly used in pharmaceutical,chemical,food electronic, plastic and metallurgical industries.Machine for precision machined stainless steel made of aluminum alloy bracket for the upper and lower independent

Learn MoreGZPK660 Automatic Double Discharge High-speed Tablet Press

U7彩票GZPK660 double discharge high-speed rotary tablet press is designed with double forced feeding and double discharge structure. The process of filling, metering, pre pressing, main pressing and tablet discharging is completed twice a week by rotating the punching plate. The equipment has stable working performance, stable machine operation and low noise. Replace one set of guide rail, press double-layer piece.

Learn More